When you take a look at the UN Sustainable Growth Objectives, it’s clear that robots have an enormous position to play in advancing the SDGs. Nonetheless the sphere of Sustainable Robotics is extra than simply the appliance space. For each software that robotics can enhance in sustainability, it’s important to additionally handle the query – what are the extra prices or advantages all the way in which alongside the provision chain. What are the ‘externalities’, or extra prices/advantages, of utilizing robots to resolve the issue. Does using robotics carry a lower or a rise to:

- energy prices

- manufacturing prices

- labor prices

- provide chain prices

- provide chain mileage

- uncooked supplies consumption

- and uncooked materials alternative

Fixing our financial and environmental international challenges mustn’t contain including to the present issues or creating new ones. So it’s vital that we glance past the primary order methods wherein robotics can clear up international sustainable growth objectives and handle each stage at which robotics can have an effect.

Right here I suggest 5 ranges of sustainability to border the dialogue, a lot because the 5 ranges of autonomy have helped outline the levels of autonomous mobility.

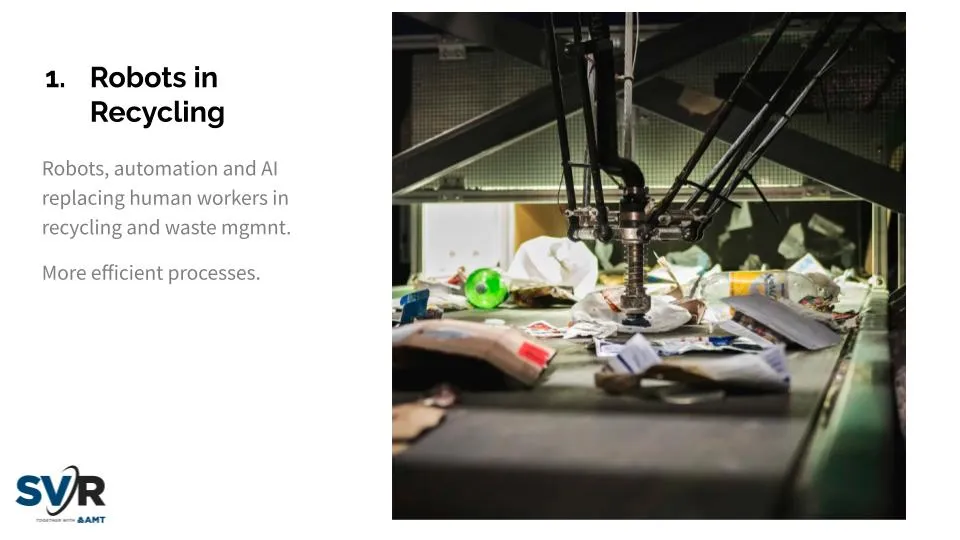

Stage 1: Robots for present recycling

Stage 1 of Sustainable Robotics is just making present processes in sustainability extra environment friendly, inexpensive and deployable. Making recycling higher. Firms which can be nice examples are: AMP Robotics, Recycleye, MachineEx, Pellenc ST, Greyparrot, Everlast Labs and Fanuc. Right here’s an explainer video from Fanuc.

“Due to AI, due to the robotic arms, we now have seen crops get better 10, 20, 30% greater than what they’ve been doing beforehand,” mentioned JD Ambati, CEO of EverestLabs. “They’ve been dropping hundreds of thousands of {dollars} to the landfill, and due to AI, they have been in a position to determine the worth of the losses and deploy robotic arms to seize that.”![]()

Another examples of Stage 1 use robots to raised monitor aquaculture, or robots to wash or set up photo voltaic farms and wind generators. If the robotics know-how improves present recycling practices then it’s at Stage 1 of Sustainable Robotics.

Stage 2: Robots enabling new recycling

Stage 2 of Sustainable Robotics is the place robotics permits new supplies to be recycled and in new trade software areas. An amazing instance of that is City Machines, which salvages timber from building websites and transforms it again into useable supplies, one thing that was too tough to do at any scale beforehand.

Development utilizing onsite supplies and robotics 3D printing is one other instance, as seen within the NASA Habitat Problem, sponsored by Caterpillar, Bechtel and Brick & Mortar Ventures.

Another examples are the ocean or lake going rubbish gathering robots like Waste Shark from Ran Marine, River Cleansing, or Searial Cleaners, a Quebec firm whose robots have been deployed within the Nice Lakes Plastic Cleanup, serving to to take away 74,000 plastic items from 4 lakes since 2020.

Searial Cleaners is angling for its BeBot and PixieDrone for use as janitorial instruments for seashores, marinas and golf programs, and the BeBot provides ample room for firm branding. The gear emerged from the mission of the Nice Lakes Plastic Cleanup (GLPC) to harness new applied sciences in opposition to litter. This system additionally makes use of different units together with the Seabin, which sits in water and sucks in trash, and the Enviropod LittaTrap filter for stormwater drains.![]()

If it’s a model new technique to follow recycling with robotic know-how, then it’s at Stage 2 of Sustainable Robotics.

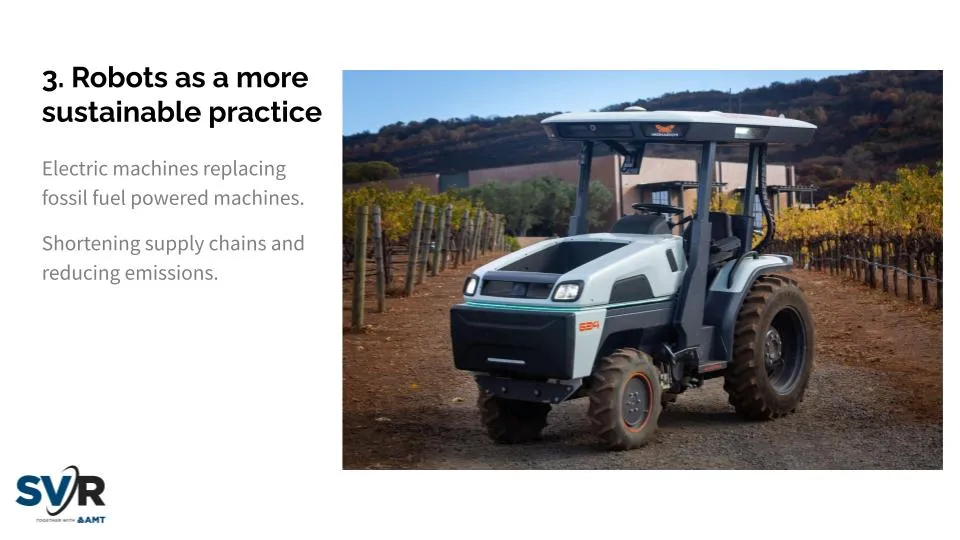

Stage 3: Robots electrifying all the pieces

One of many largest sustainability shifts enabled by robotics is the transition from fossil gas powered transport, logistics and agricultural equipment into BEV, or Battery Electrical Car know-how. On prime of radically lowering emissions, the growing use of smaller autonomous electrical autos throughout first, final and center mile can change the overall variety of journeys taken, in addition to lowering the necessity for big autos which can be partially loaded taking longer journeys.

Monarch Tractor’s MK-V is the world’s first electrical tractor, and is ‘driver non-obligatory’, which means it may be pushed or function autonomously, offering larger flexibility for farmers. In fact the elevated use of laptop imaginative and prescient and AI throughout all agrobots improve sustainability, by enabling precision or regenerative agriculture with much less want for chemical options. Technically, these enhancements to agricultural follow are Stage 2 of Sustainable Robotics.![]()

Nonetheless, using smaller sized totally autonomous agricultural robots, similar to Meropy, Burro.ai, SwarmFarm, Muddy Machines and Small Robotic Firm additionally reduces the scale and soil compaction related to agricultural equipment, and make it attainable to have a tendency smaller strip farms by machine. ![]() That is Stage 3 of Sustainable Robotics.

That is Stage 3 of Sustainable Robotics.

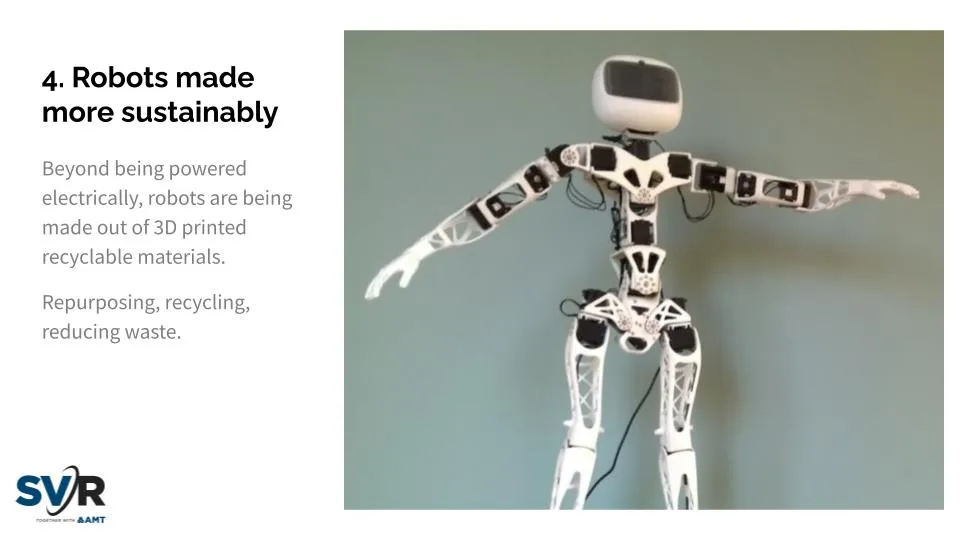

Stage 4: Robots

The upper the sustainability stage, the deeper it’s into the precise design and building of the robotic system. Switching to electrical from fossil fuels is a small step. Switching to regionally sourced or produced supplies is one other. Switching to recyclable supplies is one other step in direction of totally sustainable robotics.

OhmniLabs make the most of 3D printing of their robotic building, permitting them to export robots to 47 nations, whereas additionally manufacturing regionally in Silicon Valley.

In the meantime, Cornell researchers Wendy Ju and Ilan Mandel have launched the phrase ‘Garbatrage’ to explain the chance to prototype or construct robots utilizing parts recycled from different shopper electronics, like these hoverboards.

“The time is ripe for a follow like garbatrage, each for sustainability causes and contemplating the worldwide provide shortages and worldwide commerce problems with the previous few years,” the researchers mentioned. ![]()

It is a nice instance of Stage 4 of Sustainable Robotics.

Stage 5: Self-powering/repairing Robots

Self powering or self repairing or self recycling robots are the Stage 5 of Sustainable Robotics. In analysis, there are answers like MilliMobile: A battery-free autonomous robotic able to working on harvested photo voltaic and RF energy. MilliMobile, developed on the Paul G. Allen College of Pc Science & Engineering, is the scale of a penny and might steer itself, sense its atmosphere, and talk wirelessly utilizing power harvested from mild and radio waves.

It’s not simply analysis although. Within the final two years, plenty of photo voltaic powered agricultural robots have entered the market. Solinftec has a photo voltaic powered spray robotic, as has EcoRobotix and AIGEN, which can also be powered by wind.

Modular robotics will cut back our materials wastage and power wants by making robotics multipurpose, fairly than requiring a number of specialist robots. In the meantime self powering and self repairing applied sciences will enable robots to enter many beforehand unreachable areas, together with off planet, whereas eradicating our reliance on the grid. As robots incorporate self repairing supplies, the product lifecycle is elevated. That is Stage 5 of Sustainable Robotics.

And sooner or later?

Whereas we’re ready for the longer term, listed below are a few assets for turning your whole firm right into a sustainable robotics firm. Sustainable Manufacturing 101 from ITA, the Worldwide Commerce Administration and the Sustainable Manufacturing Toolkit from the OECD.

References

- https://www.cnbc.com/2023/08/08/everestlabs-using-robotic-arms-and-ai-to-make-recycling-more-efficient.html

- https://www.greenbiz.com/article/great-lakes-are-awash-plastic-can-robots-and-drones-help

- https://www.economist.com/science-and-technology/2020/02/06/using-artificial-intelligence-agricultural-robots-are-on-the-rise

- https://www.wired.co.uk/article/farming-robots-small-robot-company-tractors

- https://information.cornell.edu/tales/2023/09/garbatrage-spins-e-waste-prototyping-gold

Andra Keay

is the Managing Director of Silicon Valley Robotics, founding father of Ladies in Robotics and is a mentor, investor and advisor to startups, accelerators and assume tanks, with a powerful curiosity in commercializing socially constructive robotics and AI.

Andra Keay

is the Managing Director of Silicon Valley Robotics, founding father of Ladies in Robotics and is a mentor, investor and advisor to startups, accelerators and assume tanks, with a powerful curiosity in commercializing socially constructive robotics and AI.