As we embark on a brand new 12 months, a urgent query arises: What are the defining traits that may form the way forward for our business? Terry Keyworth of TOMRA Recycling offers precious insights into the important thing traits in sorting and recycling.

- Deep studying

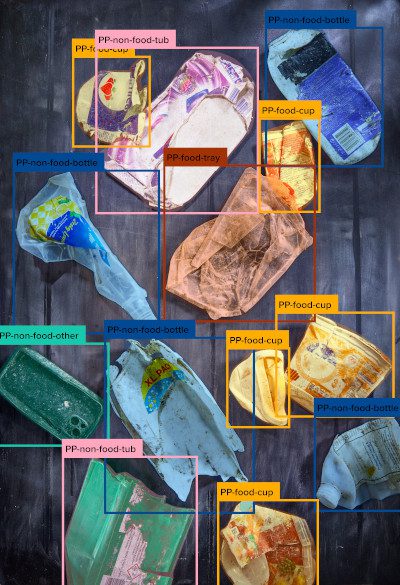

Deep studying will proceed to form the recycling business in 2025. This subset of synthetic intelligence (AI) achieved vital milestones in sorting final 12 months, resembling separating food-grade and non-food-grade plastics. Deep studying is poised to deal with more and more complicated sorting duties and increase into new segments, resembling steel sorting, unlocking new ranges of effectivity and sustainability within the recycling business.

Conventional methods, which stay important as a result of many years of refinement, deal with sorting by materials sort (NIR sensors) or color (VIS sensors). Deep studying’s worth lies in object recognition utilizing full-colour cameras which recognise the sorts of objects based mostly on form, measurement, dimensions and extra. Methods like TOMRA’s GAINnext™ use deep studying to imitate human imaginative and prescient and might be exactly educated to automate sorting challenges beforehand undertaken manually.

- Actual-time monitoring

In 2025, superior AI and cloud applied sciences shall be more and more utilised for waste evaluation, enhancing transparency in sorting amenities. Platforms like TOMRA Perception acquire knowledge instantly from sorting methods, whereas instruments like PolyPerception’s waste analyser use cameras for real-time waste monitoring and classification at key sorting factors.

Digital twins of sorting strains permit detailed object monitoring and evaluation. These methods allow operators and recyclers to make data-driven choices to enhance output high quality, forestall materials loss and preempt potential disruptions. The advantages embrace enhanced effectivity and compliance with regulatory requirements.

- European Packaging and Packaging Waste Regulation (PPWR)

The European Packaging and Packaging Waste Regulation (PPWR) shall be a important focus in 2025 as a result of its far-reaching affect on the business.

With the 2030 goal of 70% recyclability for all packaging looming, corporations should urgently adapt to strict necessities for recyclability and sturdy infrastructure. The PPWR mandates that plastic packaging should comprise a minimal of 10-35% recycled content material by 2030 – relying on the kind of plastic and its supposed use – with greater targets set for 2040.

These targets will drive improvements in eco-design and recycling applied sciences, together with superior mechanical recycling and chemical recycling.

The PPWR offers the business with planning certainty and encourages funding, notably in recycled content material demand for plastics, probably serving to to stabilize costs for recycled supplies. Optimistic developments on this regard could emerge as early as this 12 months.

- Decarbonisation: aluminium recycling

Decarbonisation will stay a precedence in 2025, notably within the aluminium sector. Many giant corporations are dedicated to net-zero targets, driving demand for recycled aluminium and high-quality feedstock.

Utilizing recycled aluminium yields vital CO2 financial savings in comparison with different supplies. Attaining ‘inexperienced’ aluminium requires elevated aluminium sorting and higher granularity, resembling separating aluminium alloys (1xxx, 3xxx, 5xxx or 6xxx sequence) into high-purity fractions. LIBS (Laser-Induced Breakdown Spectroscopy) expertise stays groundbreaking on this space, and TOMRA plans to put in a number of AUTOSORT™ PULSE methods globally in 2025.

- Give attention to lesser-known materials streams

Whereas recycling plastics, natural waste and aluminium is well-established, the recycling of different materials streams are nonetheless of their infancy and can achieve consideration in 2025.

For instance, wooden sorting applied sciences now allow the manufacturing of recycled supplies matching the standard of virgin uncooked supplies. Processed and unprocessed wooden might be separated and medium-density fibreboard recovered effectively. This 12 months may see these options applied on an industrial scale. Equally, developments in textile recycling are poised to showcase what’s technologically possible, paving the way in which for larger-scale adoption.

From revolutionary sorting applied sciences to regulatory-driven adjustments, 2025 guarantees to be a transformative 12 months for the UK recycling business!